Project Description

Product Description

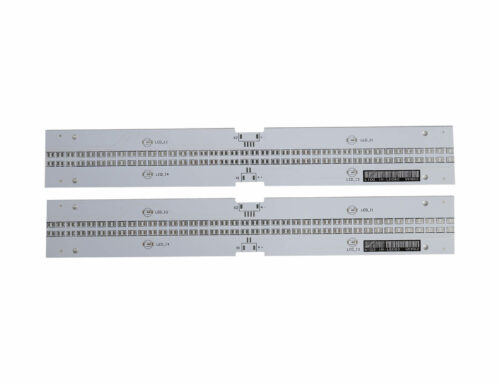

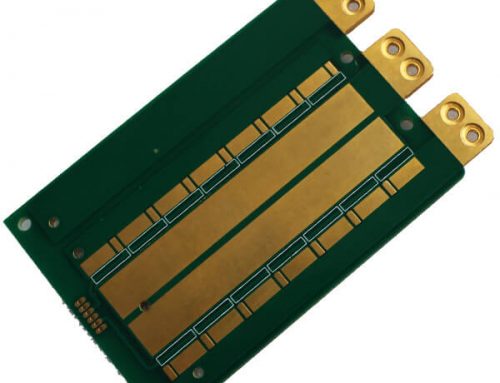

Base Material:Copper pcb

Layer No:1 Layer

Copper Thickness: 1oz

Board Thickness:1.6mm

Min.Hole Size: 1.0mm

Solder Mask: White

Silkscreen:/

Suface Finishing:Immersion gold

Testing way:ET

Tolerance of hole position:0.05MM

Standards:IPC Class 2, Class 3

Advantage for Metal Core PCBs

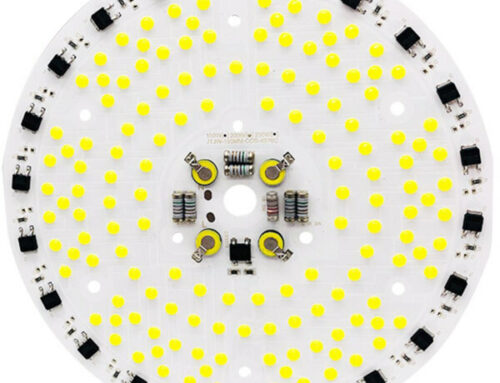

An LED PCB board tends to generate a high volume of heat, making it difficult to cool via traditional means. Consequently, metal core PCBs are frequently chosen for LED application due to their enhanced ability to dissipate heat.

Aluminum in particular is often used to manufacture circuit boards for LED lights. The aluminum PCB typically includes a thin layer of thermally conductive dielectric material that can transfer and dissipate the heat with much greater

efficiency than a traditional rigid PCB.

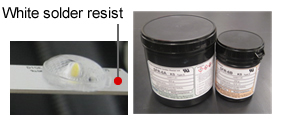

For White Solder Resist

This is the white solder resist for LED printing circuit board. Sekisui’s white solder resists have high reflectivity and high heat resistant properties (no yellowing). We provide photo-imageable and ultraviolet-cured type.

- White photo-imageable solder resist ~SFR-6 series~

- UV-curable White Solder Resist ~SR-10 KC7 Series~

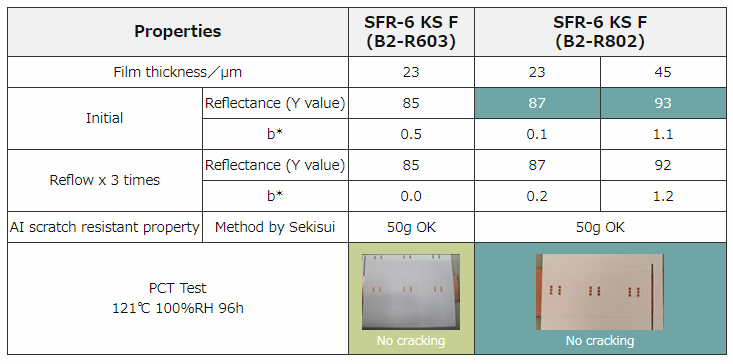

White photo-imageable solder resist

~SFR-6 series~

This is the white photo-imageable solder resist (WPSR). SEKISUI provide standard and high reflectance WPSR.

Characteristic 1

1, Super high reflectance (B2-R802) (Filled with high density of TiO2)

2, Highly heat resistance (no yellowing & highly crack-resistant)

3, High reliability (PCT etc.)

Characteristic 2

SFR-6 Series have high heat resistance and reliability.

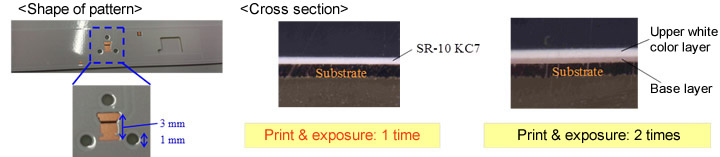

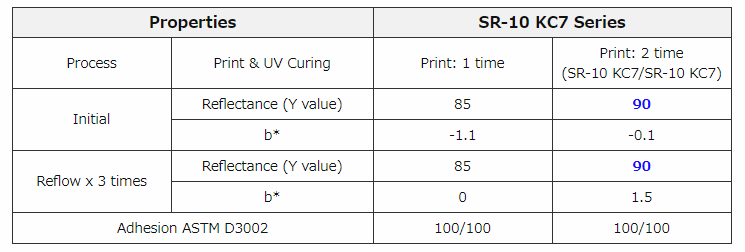

UV-curable White Solder Resist

~SR-10 KC7 Series~

This is the UV-curable white solder resist (UV-SR). SEKISUI provide high reflectance and adhesion UV-SR.

SR-10 KC7 series have high adhesive property and reflectance.

Package

| Materials : | Foam + Carton |

| Carton size : | 27*27*30CM |

| Carton Capacity : | 1pcs/carton |

| Gross weight : | No more then 20kg/carton |

-

Sample fee refund policy

-

Any inquiry or complain can be responded in 12 hours Eco-friendly, conforming to the law of environmental protection and carbon reduction plan