Project Description

Product Description

Base Material:Rigid-Flex PCB

Layer No:2 Layer

Copper Thickness: 1oz

Board Thickness:1.0mm

Min.Hole Size: 0.3mm

Solder Mask: Green

Silkscreen:/

Suface Finishing:Immersion gold

Testing way:ET

Tolerance of hole position:0.05MM

Standards:IPC Class 2, Class 3

Advantage for H-CELERITY

In 2014, H-Celerity PCB Limited put into operation two Full-automatic screen printing lines, two Full-automatic coating lines and three 1.55*0.85M Big Table-board LED Exposing Machine, giving the daily delivery capacity of backlight source circuit board of up to 2000-3000 square meters. Faced with customers’ requirements for the quality of ink color difference and reflectivity of backlight products, in order to ensure the quality, H-CELERITY has purchased advanced testing equipment such as color difference meter, reflectivity tester and ink film thickness tester for backlight source products. In order to further improve the reflectivity and color difference of ink, H-CELERITY has also developed special LED ink and OSP formula with ink manufacturers and OSP surface treatment venors. Now, the comprehensive reflectivity of high-reflective LED ink can be over 83, and OSP surface treatment can withstand high temperatures for three times, reaching a higher level in the industry. At present, the maximum size of LED board can be 1500*550MM. Now, H-CELERITY’s main customers include Opple, MTC, Yankon, Nation Star, Topstar, KTC, Philips and other well-known customers at home and abroad.

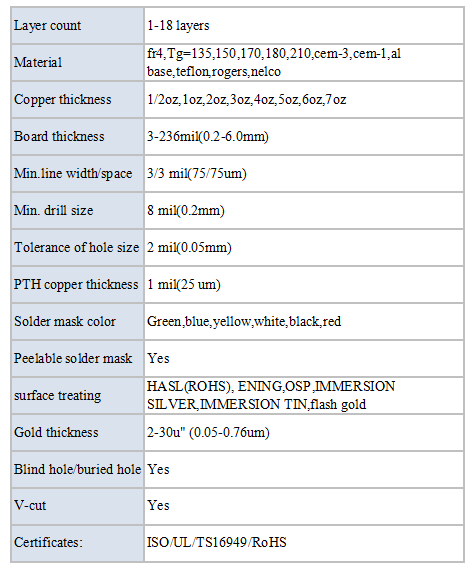

Pcb capability

Package

| Materials : | Foam + Carton |

| Carton size : | 20*16*150CM |

| Carton Capacity : | 1pcs/carton |

| Gross weight : | No more then 20kg/carton |

-

Sample fee refund policy

-

Any inquiry or complain can be responded in 12 hours Eco-friendly, conforming to the law of environmental protection and carbon reduction plan